Table of Contents

Introduction

In the kurti business, good sales figures don’t always mean good profits. Many retailers, wholesalers, and boutique owners manage to sell a steady volume every month, but when they look at the final numbers, the margins are often disappointing. Increasing fabric rates, higher labor costs, rising transport expenses, and price-conscious customers have made the apparel market tougher than ever. Today, earning better profits is not just about selling more pieces. It depends largely on where and how you source your products.

This is where Kurti manufacturers in Surat make a real difference. Over the years, Surat has become a trusted sourcing hub for B2B kurti buyers across India. Not because of marketing hype, but because the city’s strong manufacturing setup helps businesses control costs, maintain a steady supply, and grow at scale without constant margin pressure.

We will break down in a simple and practical way how sourcing from Surat kurti manufacturers can help you protect your profits and gradually improve your margins as your business grows.

Why Profit Margins Matter More Than Sales Volume in B2B Apparel

People often confuse sales and profit in the wholesale and retail apparel business. Big sales numbers may look good on paper, but if the margins are weak, they quickly start affecting cash flow and day-to-day operations. Low margins leave very little room to handle returns, slow-moving designs, seasonal ups and downs, or sudden expenses that come with running a fashion business.

Profit margins matter because they decide how comfortably you can grow. When margins are stable, you can invest in new designs, stock wider ranges, and plan expansion with confidence. But when profits are thin, every decision becomes risky, and the business is always under pressure. In the kurti segment, where designs change frequently and trends move fast, maintaining steady margins becomes even more important.

That’s why experienced buyers don’t focus only on getting the lowest price. They focus on buying smart. And for most successful kurti businesses, that smart decision begins with choosing the right manufacturing partner.

Understanding How Margins Are Created in the Kurti Supply Chain

In the kurti business, margins are decided much earlier than most people realize. They are shaped at the sourcing and manufacturing stage, not at the billing counter. When kurtis move through multiple layers like agents, traders, and stockists, every extra hand adds its own cost. Unfortunately, these added costs rarely increase the value of the product for the final buyer.

Direct sourcing from manufacturers eliminates many unnecessary markups. This provides buyers with enhanced pricing control and increased cost transparency. Factors like how efficiently the factory runs, how large the production scale is, where fabrics are sourced from, and how processes are managed all help keep the base cost competitive. Effective management of these factors results in lower landed costs and healthier selling margins for buyers.

Such efficiency is one of the key reasons why many B2B buyers prefer working with Kurti manufacturers in Surat, where production is well-organized, specialized, and designed to handle volume efficiently.

Why Surat Is a Strategic Manufacturing Hub for Kurtis?

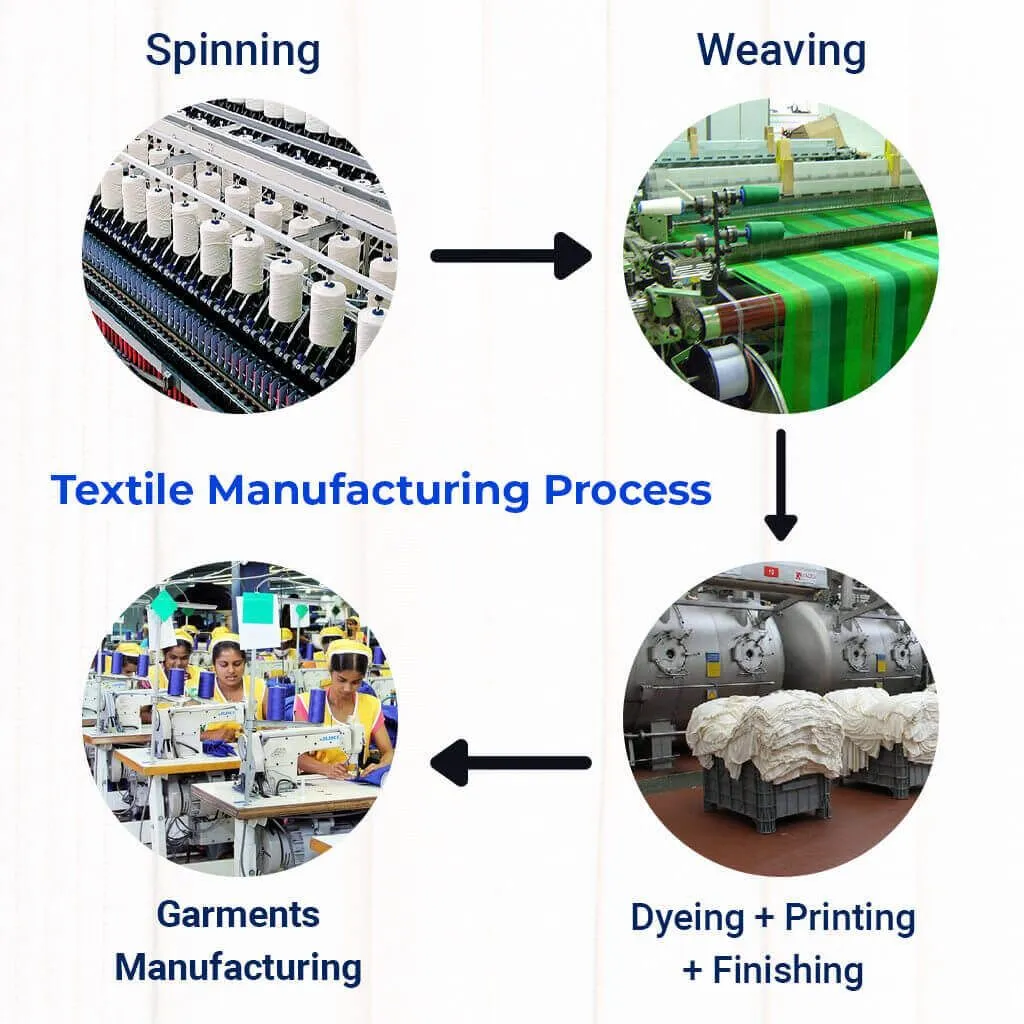

Surat’s biggest advantage is its complete textile ecosystem. Unlike places where different production steps are scattered across locations, Surat has everything connected in one system. Fabric sourcing, dyeing, printing, stitching, finishing, and packing all take place in close proximity. This strong network helps reduce delays, cuts transportation expenses, and avoids many coordination problems that usually slow down production.

The city also has a highly experienced workforce that has been part of the garment industry for years. Because manufacturers work with large production volumes, they are able to manage costs better while maintaining consistent quality across batches. These structural strengths make Surat a reliable and cost-effective sourcing destination for B2B buyers.

For kurti businesses, this translates into more stable pricing, quicker order completion, and a supply chain that runs smoothly without unexpected disruptions.

Direct Manufacturer Pricing Helps Buyers Secure Better Margins

One of the biggest benefits of sourcing from Surat is getting factory-direct pricing. When buyers deal directly with kurti manufacturers, they avoid extra layers of commissions and charges that usually push prices up when products pass through agents or traders.

Working directly with manufacturers also brings more transparency. Buyers know exactly what they are paying for and can negotiate better based on order quantity, repeat business, and long-term potential. This makes it easier for retailers and wholesalers to plan their selling prices with confidence and stay competitive without sacrificing margins.

For B2B buyers, sourcing directly from manufacturers is not just about buying at a lower price. It is about building a predictable and sustainable profit structure that supports long-term business growth.

Consistent Quality Reduces Returns and Protects Your Margins

Returns are one of the biggest silent profit killers in the apparel business. Problems like size mismatch, weak stitching, fabric issues, or color differences often lead to customer complaints, exchanges, or unsold stock. While each return may seem small, together they slowly reduce your overall profit.

Established Kurti manufacturers in Surat pay close attention to quality consistency because their business relies on long-term buyers, not one-time orders. They follow standard production processes, check quality at multiple stages, and have experience handling bulk orders, which helps keep every batch uniform.

When quality stays consistent, retailers deal with fewer returns, stock moves faster, and customer confidence grows. Over time, this reliability plays a major role in improving and protecting business margins.

Faster Design Turnaround Improves Inventory Rotation

Margins are not only decided by how much you pay for a product but also by how fast it sells. When designs move slowly, retailers are forced to give discounts or clear stock, which directly reduces profits. On the other hand, fresh and updated designs sell faster and allow better pricing.

Surat manufacturers are quick to understand what the market wants. Because fabric markets, design teams, and production units are closely connected, new styles can be developed and produced without long delays. This helps buyers update their collections regularly instead of waiting months for new designs.

When designs reach the market faster, stock rotation improves, collections stay relevant, and the need for heavy discounting goes down. Over time, this speed and flexibility play a big role in protecting and improving margins.

Bulk Production Readiness and MOQ Flexibility Support Business Growth

Not every B2B buyer is at the same stage of business. Some are just starting and want to place small trial orders, while others need large quantities across multiple designs. Surat kurti manufacturers are used to working with different types of buyers and order sizes, which makes the sourcing process smoother.

Many manufacturers in Surat offer flexible MOQs for new buyers and are also equipped to scale production as the business grows. This flexibility helps retailers and wholesalers test new designs, see how the market responds, and then increase volumes with confidence, without blocking too much money in unsold stock.

This kind of adaptability lowers financial risk and allows businesses to grow step by step while keeping margins under control.

Faster Dispatch and Reliable Supply Enable Better Sales Planning

Unclear delivery timelines can disturb the entire sales plan, especially during festive seasons and peak demand periods. When supply is unreliable, retailers risk missing sales opportunities and face unnecessary pressure on cash flow. For any B2B business, a steady and dependable supply is critical to meeting customer commitments.

Surat’s strong manufacturing setup supports faster production and more reliable dispatch schedules. When buyers know exactly when their orders will be ready, they can plan promotions, seasonal collections, and bulk sales with much more confidence.

This kind of operational reliability reduces day-to-day stress, prevents last-minute sourcing at higher prices, and keeps the business running smoothly. Over time, a well-organized supply chain helps protect margins and improves overall efficiency.

Long-Term Manufacturer Relationships Lead to Better Margins Over Time

In B2B apparel, better margins usually come with stronger relationships. When buyers work consistently with the same manufacturer, they often receive better pricing, priority in production, and early access to new designs. Over time, the relationship becomes less about one-time deals and more about mutual trust, which benefits both sides.

Experienced kurti manufacturers in Surat value long-term buyers because steady orders help them plan production more efficiently. In return, buyers get smoother processes, stronger negotiation power, and a more reliable supply without constant follow-ups.

This relationship-based way of doing business is often overlooked, but it is one of the most effective and sustainable methods of improving margins in the long run.

How to Choose the Right Surat Kurti Manufacturer for Sustainable Profits

Not every manufacturer offers the same level of value. Before finalizing a supplier, buyers should look beyond pricing and check things like manufacturing experience, quality control standards, how often designs are updated, how clearly the team communicates, and how reliable the dispatch process is.

A good manufacturing partner is more than just a supplier. They become a support system for your business growth. Choosing the right partner helps keep margins stable, reduces daily operational issues, and allows your business to scale smoothly and confidently over time.

Conclusion

In the kurti business, healthy margins are built step by step. They come from choosing the right sourcing partners, working with manufacturers you can rely on, and having systems that keep operations smooth. Kurti manufacturers in Surat offer the right mix of cost control, consistent quality, quick design updates, and dependable supply, which together help businesses improve profitability over time.

For retailers, wholesalers, and boutique owners who want to build a strong and scalable apparel business, Surat is not just a manufacturing location; it is a real business advantage. If you are looking for a sourcing partner that understands B2B needs and supports long-term growth, ThePrintinkCo. works closely with buyers to provide reliable manufacturing and quality-focused supply. Get in touch with us to explore sourcing options that help you grow with confidence and predictable margins.